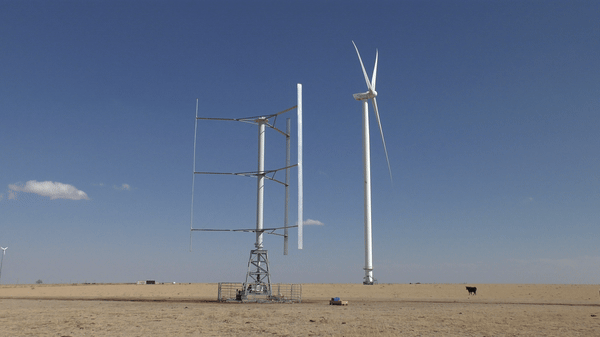

When you think of a wind energy farm, you’re likely thinking of extremely tall structures with massive “propeller type” rotors, spaced far apart from one another. Their towers can reach 300 feet or more in height, and their rotor blades are often 100 to 200 feet in length.

What’s underfoot? Mostly empty space. Even though, in many wind energy farms, there’s plenty of strong wind below 100 feet that could also be used to generate electricity.

Enter Wind Harvest. They’re a startup company headquartered in Davis, California, around 200 miles from High Sierra’s factory,

Wind Harvest makes much smaller, boxy-shaped wind turbines that rotate in the horizontal plane around a vertical axis. They’re simpler to make, install, and operate than the giant, traditional turbines and have fewer moving parts.

Plus, they’re extremely sturdy. They need to be, too, because the near-ground (aka “mid-level”) winds their turbines harvest can be highly turbulent, unlike the smoother winds higher up. Their components, which can be assembled on or near a project site, are made from durable and recyclable aircraft aluminum and steel and are installed on shallow concrete foundations. (That’s in contrast to the fiberglass and resin blades of larger turbines, which typically just end up in landfills, and deep foundations which are hard to remove.)

While Wind Harvest’s shorter turbines can be installed in many places, including urban, rural, and even off-grid sites, their most intriguing application is as “infill” within existing wind farms. Around 20% of wind farms worldwide are estimated to have excellent near-ground wind resources. By filling the spaces between existing large wind turbines, their Wind Harvester® vertical axis wind turbines can often double or more the total electricity generated from wind farms and thus reduce the need to build new wind and solar farms on raw land.

While the fundamental tech behind Wind Harvest’s turbine design dates back to 1976, the company has recently come much closer to commercial production. With seven new patents granted and Technology Readiness Level (TRL) 7 behind them, they are now seeking to complete TRL 8 (Final Commercial Product Certification by a third party) and TRL 9 (Bank-Financeable Product). And they’re already taking applications for prospective projects and sales.

In this interview with Eric A. Cox II of Netcapital, Kevin Wolf, CEO & Co-Founder of Wind Harvest, explains how turbulent, near-ground winds – which bounce, spin, rise, and fall – are a vast, untapped resource in existing wind farms.

This story appeared in the June 2025 issue of High Sierra Droplets, our monthly newsletter.

Want to read more stories like this? Subscribe for free today!